Sorter

When pellets come out of the screen they have to be sorted correctly to be reused. Therefore, the pellets must be sorted and put back into a place where they can be sent back to the screen again.

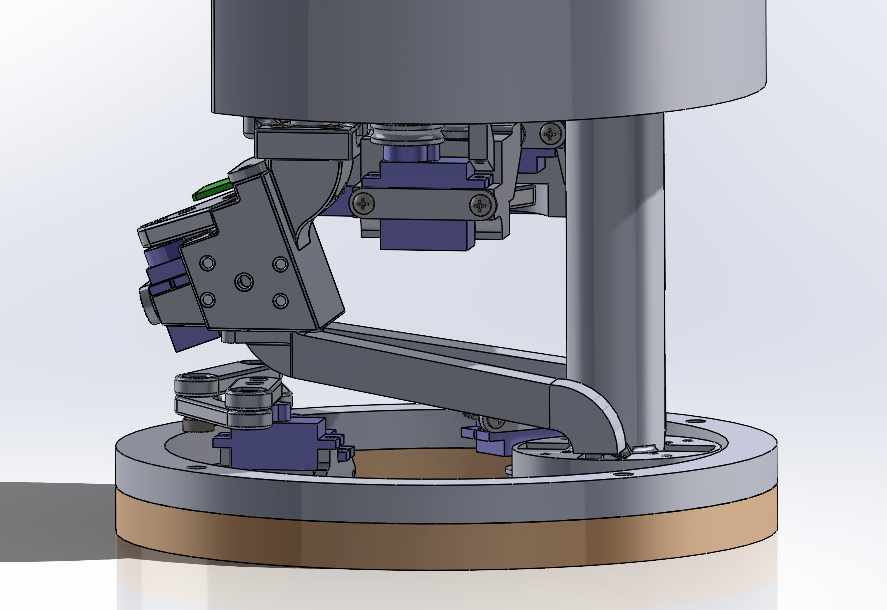

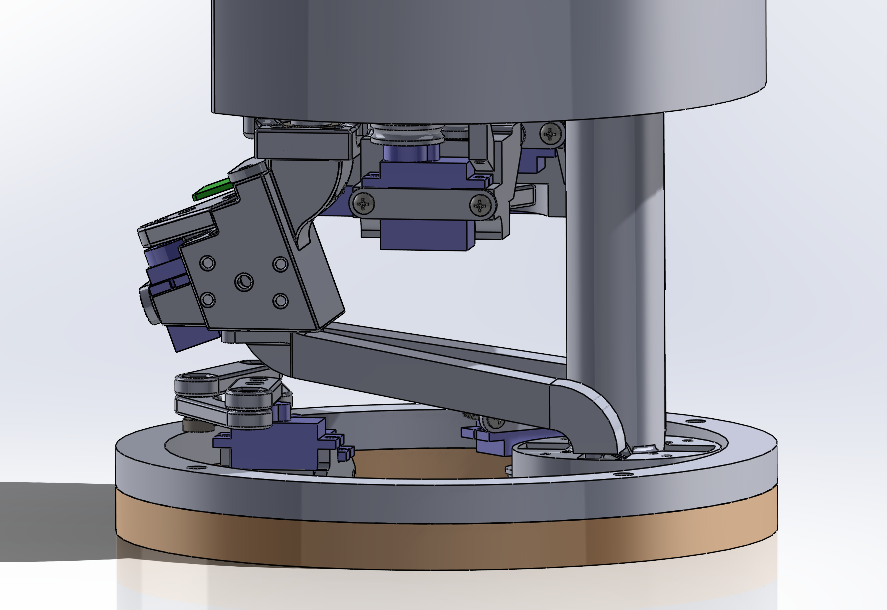

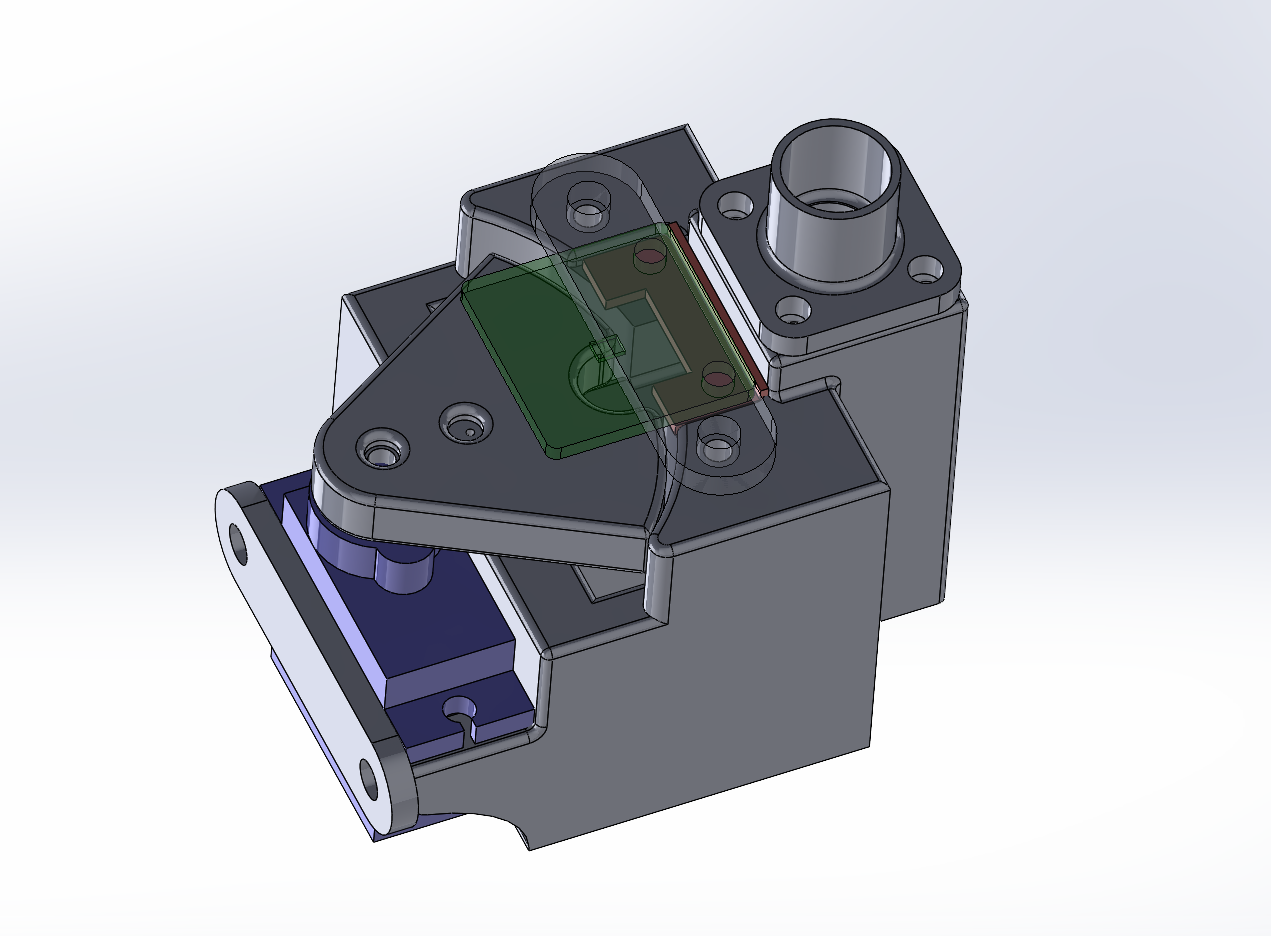

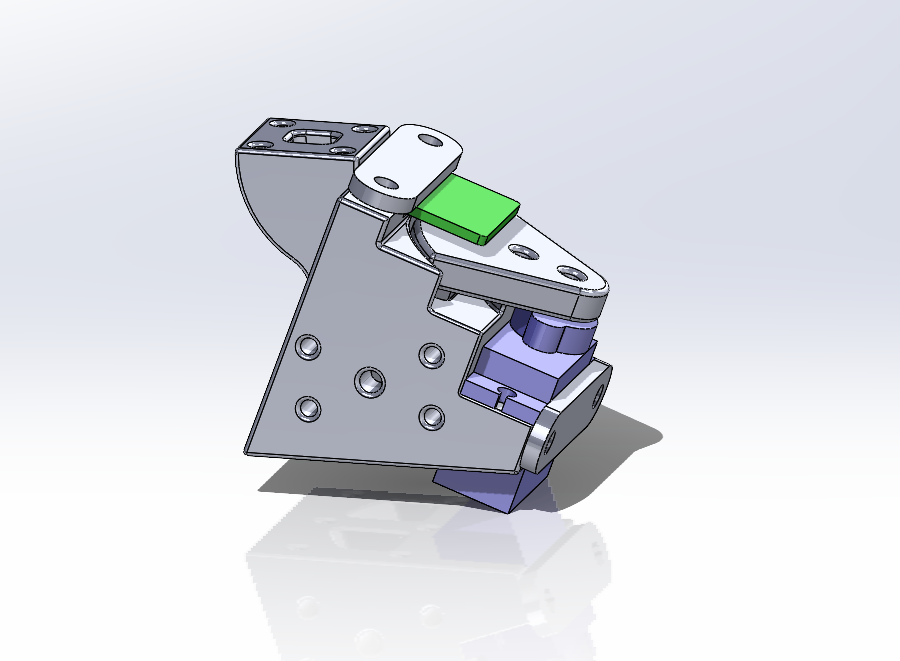

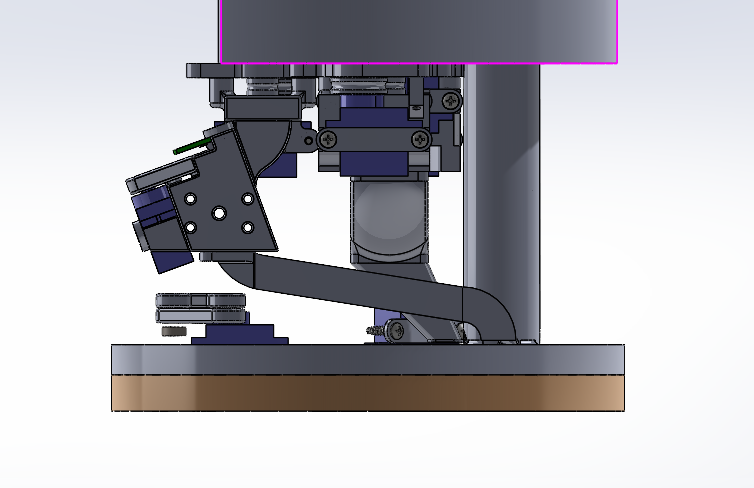

Once the pellets leave the screen they are sent to a reservoir above the sorter. They then flow from the reservoir to a color sensor (orange arrow in the image to the right). Once the color sensor scans them they are sent down the appropriate path to the base of the auger (red arrow in image). The two paths to the auger are shown better in the image below. From the base of the auger, the pellets are sent up into their respective reservoirs. Because this display only uses black and white pellets, the sorter only has to split the balls into two streams.

Flow of Pellets through the Sorter

Both Paths Visible of Sorter to Augur Base

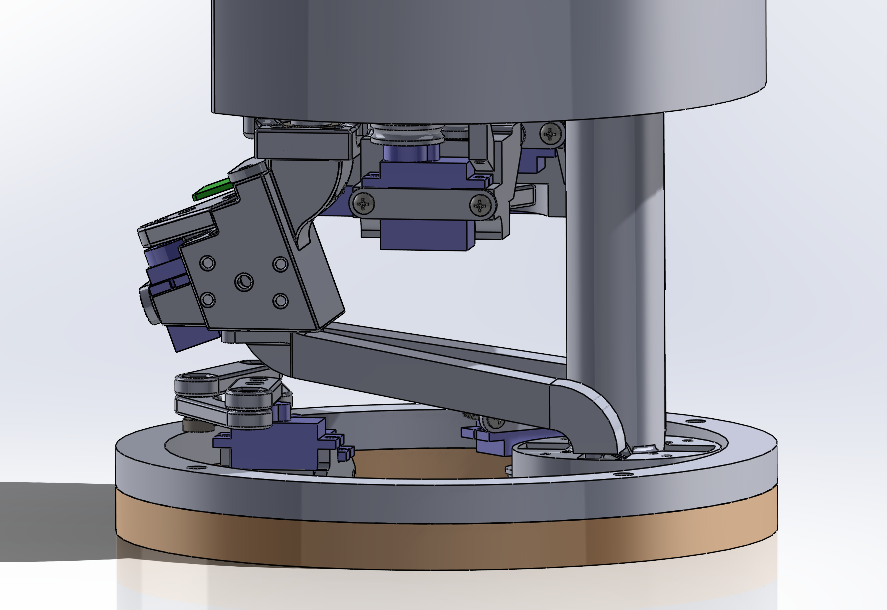

Angled View

Components

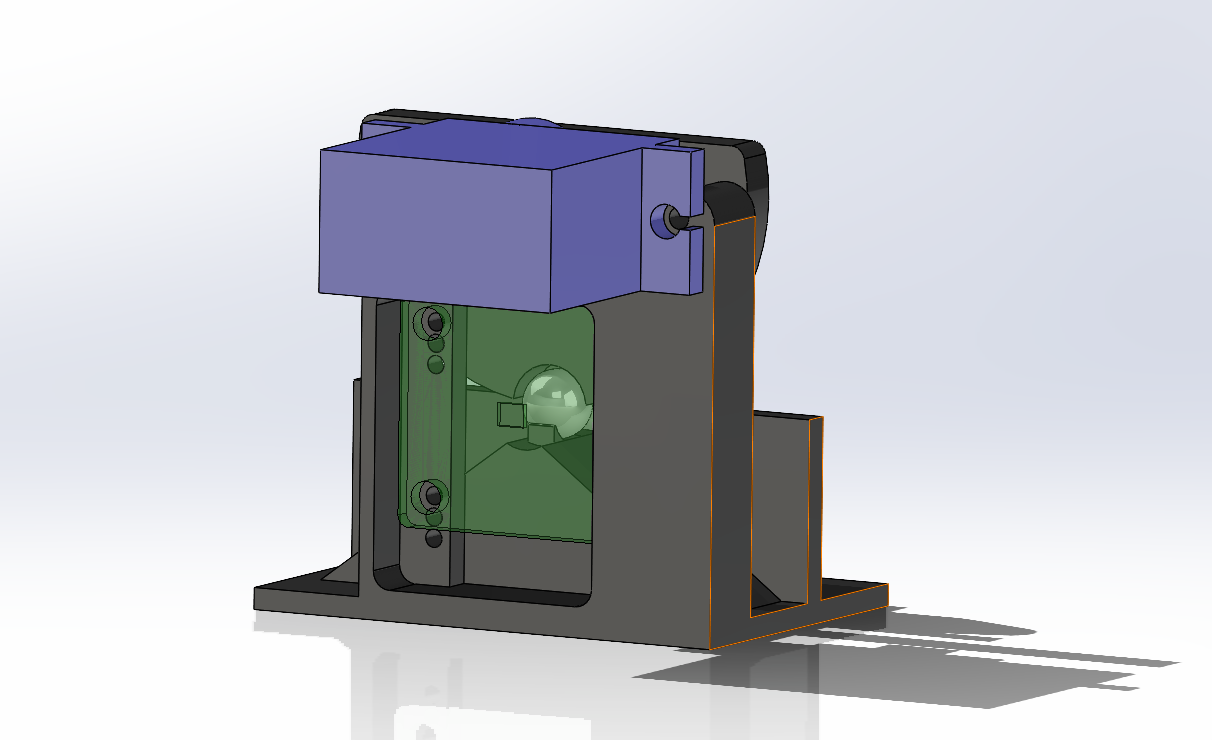

The sorter is composed of a servo and a color sensor. The color sensor measures the RGB value of the pellet and the servo pushes down the appropriate path. Because this screen only uses two colors of pellets, there are only two output paths from the sorter.

The color sensor I use is the TCS34725, this sensor has three photo-sensitive diodes with tunable gains and communicates using I2C.

The sorter arm is driven by a generic 9g plastic servo driven by a PWM signal. Depending on the color read by the sensor, the arm will push the pellet down one path or the other.

Flow of Pellets through the Sorter

9g Servo

Angled View

Iterations

-

Issues

The black plastic used to print this iteration was reflective. The reflections bounced back into the photodiode and gave off inconsistent readings.

The orientation of the color sensor required intricate geometry to keep the pellets away from the sensor. This geometry also partially obscured the sensor’s view of the pellet.

The color sensor was fixtured loosely and its position was not very tuneable. As a result, the photodiode never consistently pointed at the pellets.

-

Solutions to Iteration 1

I switched to using some matte grey plastic instead. This reduced the amount of noise to the photodiode.

I left room for the position of the sensor to be adjusted. By doing this, the sensor position could be tuned without having to reprint the entire sorter.

Issues

The location of the sensor relative to the pellet stream made it so the sensor could see the pellets behind the front one.

There is no incline biasing the pellets towards the sensor. The front pellet relies on being pushed by the pellets behind it. When there is not enough pressure on the front pellet, the front pellet jams the sorter.

-

Solutions to Iteration 2

After Iteration 2 was shimmed, the final position of the sensor was determined. Using this, iteration 3 required no shims and had a press-fit location for the sensor.

I put the entire sorter at an angle. This incline meant the pellets would always roll to the sensor without a need for other pellets to push them.

This was the final iteration.

Iteration 1

Iteration 1: Showing Limited View Sensor has of Pellet

Iteration 1 & 2

Iteration 2

Iteration 2 with introduced shim (red)

Iteration 3

Iteration 3 with Agitator

Iteration 3 in Final Assembly

Iteration 3 in Final Assembly